“To be or not to be” is a question that has transcended centuries. But in the orthopedics industry, it finds its modern-day equivalent: “To produce or to track?” This dilemma isn’t just philosophical, it’s a fundamental decision shaping the future of orthopedic companies.

In an industry where efficiency and precision are paramount, businesses must balance the drive to produce cutting-edge medical devices with the need to track and manage their supply chain effectively. On one hand, scaling production seems like the logical step to meet growing demand. On the other, without robust tracking systems, inefficiencies, waste, and compliance risks can erode profitability.

The stakes are even higher when you consider the cost of surgical sets, which can easily exceed $30,000 per set. Losing track of such valuable assets isn’t just a logistical headache, it’s a significant financial risk. Proper tracking ensures that these essential tools are always where they need to be, minimizing loss and maximizing operational efficiency.

So, what’s the best deal for the orthopedic industry? In this article, we’ll dive into the challenges and benefits of both approaches, explore how emerging technologies are transforming the landscape, and help you determine where your focus should lie.

Key Challenges in Orthopedic Production

- High Manufacturing Costs: Producing orthopedic devices requires advanced materials and precision engineering, driving up costs.

- Regulatory Compliance: Stringent regulations add layers of complexity and cost to the production process.

- Supply Chain Disruptions: From raw material shortages to delayed shipments, production faces numerous hurdles.

The Importance of Tracking in Orthopedics

- Asset Protection: Surgical sets worth $30,000 or more must be accounted for at all times to avoid costly losses.

- Regulatory Traceability: Tracking ensures compliance with strict healthcare regulations, protecting companies from legal risks.

- Operational Efficiency: Real-time tracking streamlines inventory management, reduces waste, and improves allocation of resources.

Technological Advancements: Bridging the Gap

Advances in technology are transforming how orthopedic companies approach production and tracking. Predictive analytics powered by IoT devices offer insights into inventory needs, reducing overproduction and ensuring critical supplies are available when needed. AI-driven systems analyze complex datasets, identifying inefficiencies in production or distribution and enabling data-informed decisions. These technologies not only enhance tracking precision but also optimize manufacturing workflows, creating a seamless integration between the two.

For example, predictive tools can forecast demand spikes, allowing companies to scale production effectively without unnecessary surplus. Simultaneously, advanced algorithms ensure inventory is accurately tracked, eliminating costly misplacements and delays. This synergy of production and tracking technologies creates a balanced, efficient system that mitigates risks while improving overall output.

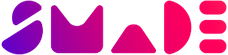

When evaluating whether to focus on production or prioritize tracking, several factors come into play. In terms of cost efficiency, focusing on production often requires a high initial investment, whereas prioritizing tracking helps reduce losses and waste. For regulatory compliance, production-focused strategies typically achieve moderate compliance, while tracking-oriented approaches offer high compliance due to robust traceability. Regarding operational complexity, production tends to involve higher complexity, while tracking is comparatively moderate. Finally, technology needs differ significantly: production demands advanced manufacturing technologies, while tracking benefits from tools from the IoT solutions, such as sensors automatically sharing their last location by automatically matching the closest network (Wi-Fi or cellular).

Striking the Perfect Balance in Orthopedics

The decision to produce or to track isn’t an either-or scenario. Both strategies are critical to success, but the scale often tips in favor of tracking. With the rising costs of surgical sets and the growing importance of regulatory compliance, robust tracking systems are becoming a non-negotiable aspect of modern operations.

Investing in cutting-edge tracking technology not only reduces financial risks but also enhances efficiency, allowing companies to focus on what they do best: innovating and delivering top-notch orthopedic solutions. The question remains: Is your company ready to embrace the future of tracking?

Spread the word !

Other posts

February 12, 2025

Discover S-HUB Makalu

It’s been a week since S-HUB Makalu has been released!

Here’s a short video highlighting the key new features of this version!

November 27, 2024

RFID vs. Auto Matching: The Future of Efficient Medical Tracking

In the orthopedic industry, one truth unites all players: time is money. Efficiently tracking your kits isn’t just a time-saver, it’s a game-changer…

If you love to write about smart healthcare, fill this form to become a writer for ‘In Your hands’.